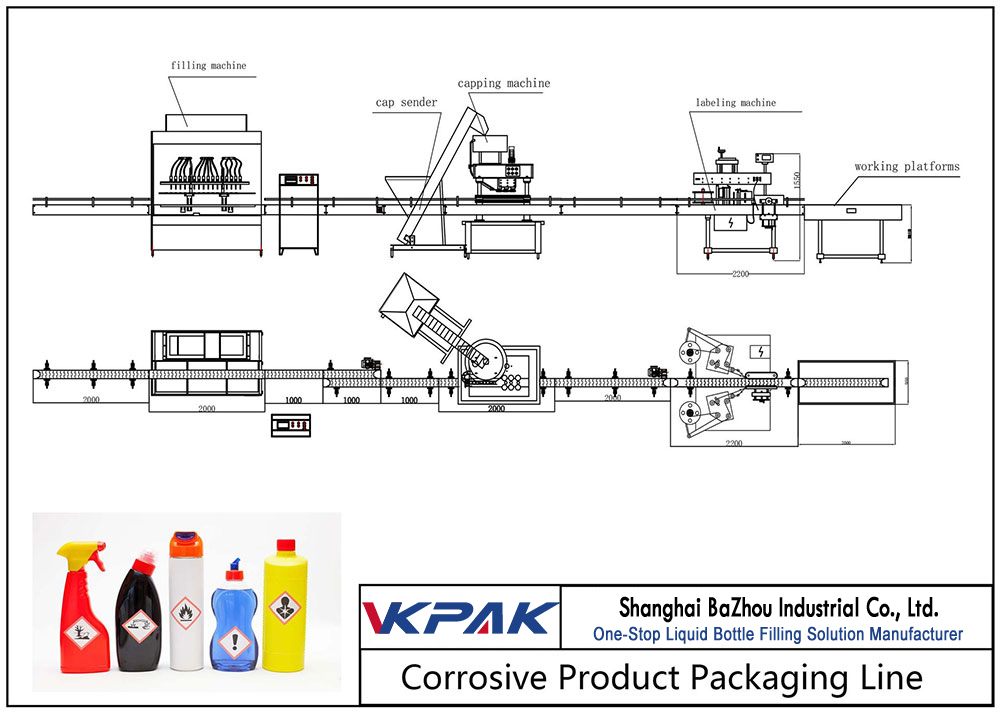

Avtomatik korroziv mahsulotni to'ldirish liniyasi

- The VKPAK Automatic Corrosive Filler (ACF) is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery. The speed and ease of use make the ACF an ideal solution for chemical plants producing acids, bleach, ammonia, as well as food plants filling aggressive brine solutions. Each ACF machine is built from corrosive resistant material custom suited to the product they are intended for. They include a 10’ variable speed conveyor built from the same corrosive resistant components.

- Avtomatik korroziy plomba moddalari, shuningdek, ish xotirasi bilan to'liq raqamli rangli sensorli displeyni, shishani to'ldirmasdan, qadam bosish yoki to'ldirish rejimlarining barchasini va shishani plyonkali plyusni sozlash moslamasini o'z ichiga oladi. Minimal o'qitish bilan ACF tizimlarini sozlash, ishlatish va sozlash oson. Ixtiyoriy ravishda barcha pnematik modellar mavjud.

- Asosiy mashinalarga quyidagilar kiradi:

- Avtomatik korroziyali suyuqlik to'ldirish mashinasi

- Avtomatik tortish mashinasi

- Avtomatik yorliqlash mashinasi

- Avtomatik indüksiyon sızdırmazlık mashinasi

- Kartonni avtomatik muhrlash mashinasi

- Avtomatik karton mashinasi

- VKPAK supplies a complete range of equipment to fill corrosive products to meet nearly any application. Made from HDPE (high density polyethylene, these filling machines, conveyors and turntables are designed to handle the punishment of a highly corrosive environment where standard metal components would normally dissolve.

- VKPAK poly filling systems use volumetric filling methods, which are extremely accurate and versatile. The fillers are designed to fill from a fraction of an ounce up to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids. VKPAK’s modular design can allow the design of the filler machines to have multiple tanks and fill head assemblies to isolate non-compatible products within a common frame. All VKPAK fillers are built to provide the best combination of maximum versatility, easy setup and changeover, and minimal down-time for maintenance and cleaning. VKPAK also manufactures this type of bottling equipment for table-top applications.

- Asosiy ishlash va tuzilish xususiyatlari:

- 1. Boshqarish tizimi - Mitsubishi PLC boshqaruv tizimi, tasodifiy sozlash dozasini to'ldirish bilan

- 2. Operatsion interfeysi - rangli ekran interfeysi, inson-mashina interfeysi oddiy, xavfsiz va ishonchli

- 3. Xususiyatlarni yaxshilash - tomchilab bo'lmaydigan asbob bilan kesish, u materiallar bilan to'ldirish uchun sho'ng'iy oladi. (Bu xususiyat ixtiyoriy bo'lishi mumkin)

- 4. Elektr komponentlari - uskunaning ishonchli va yuqori aniqligini ta'minlash uchun xalqaro taniqli brendlardan foydalanish.

- 5. Mexanik tarkibiy qismlar - asosiy qismlar yuqori sifatli PP ramkasidan, aloqa qismi toksik bo'lmagan korroziyaga qarshi silika jeli, PTFE shlanglari, vana PVXdan qilingan.

- 6. Kengaytmalar - ma'lum konfiguratsiya talablariga moslashtirilishi mumkin, masalan: material muhrlangan, isitish, sterilizatsiya va boshqalar.

- 7. Hisoblash sinovlari - to'g'ridan-to'g'ri ish natijalarini aks ettiruvchi real vaqtni hisoblash.

- 8. To'ldirishni aniqlash - shisha yo'q yoki shisha to'ldirish raqami etarli bo'lmaganda, to'ldirilmaydi

- Texnik parametrlar

| Qo'llaniladigan texnik xususiyatlar | 100-5000ml |

| Ishlab chiqarish hajmi | 1000-2500 shisha / soat (4/8/12/16 to'ldirish boshi) |

| To'ldirish aniqligi | ± 1% |

| Qo'llash tezligi | ≥99% |

| Quvvatlantirish manbai | 380V / 50Hz |

| Quvvat | 2,5 kVt |

| Umumiy o'lchov | 2500 * 900 * 2500MM |